Universal Robots’ commitment to manufacturers in Australia and New Zealand can be underpinned by its investment in its people.

Channel Development Manager Masayuki Mase looks to grow and service the local market while Senior Technical Support Engineer Ian Choo relocated from Singapore to Australia to provide engineering support and training. These senior members solidify the company’s investment in the local market and add a plethora of knowledge and experience to its local ranks.

Regional Director for Asia-Pacific James McKew says that the company’s growth strategy has been underpinned by the heightened demand for collaborative robots – robots that can work closely and safely with humans.

“Covid-19 has accelerated the demand for robotic technologies in the local market,” he says.

Local news reports have echoed this sentiment, reporting a Covid-19 enthused automation boom. This is largely due to ongoing lockdowns that continue to hamper production productivity, as well as the need for reshoring and the high cost of labour.

This requires the need for a sustainable solution.

“Globally, Universal Robots is the market leader,” says Mr McKew. “We have over 700 employees and 1100 partners and are set to increase our local footprint.”

This uptick for cobots has been reflected in Universal Robots’ latest quarterly results.

“Globally, our company reported 75% growth in revenue year-on-year,” says Mr McKew. “This goes to show that cobots are now increasingly part of the solution.”

He adds that Australia and New Zealand have been earmarked as key regions for investment.

“The trend towards automation cannot be ignored,” he says. “Our company is committed to the local market, and this is signaled through the recruitment of two senior team members.”

With three years’ experience at Universal Robots prior to his new role, Mr Choo explains that his new appointment has seen him focuses on assisting prospective customers with application consultations as well as providing deployment and post-deployment support to end users and system integrators in Australia and New Zealand.

“Training is fundamental to our offering and as such, my role includes technical product training,” he says.

Among his academic accolades, Mr Mase has 10 years’ experience in industrial automation, 18 months of which has been at Universal Robots.

“My primary responsibilities are to manage and develop the sales channels as country manager for Australia and New Zealand,” he says. “I also act as local key account Manager for Toyota Group.”

Working through the challenges, together

Speaking to the sustained demand for automation, Mr Mase believes that one of the biggest challenges plaguing manufacturing businesses is “how to remain competitive in today’s economy”.

“Manufacturers in Australia and New Zealand are no exception; global companies are leading the movement to evidently expedite automation adoption, thereby reducing costs and increasing efficiencies,” he says.

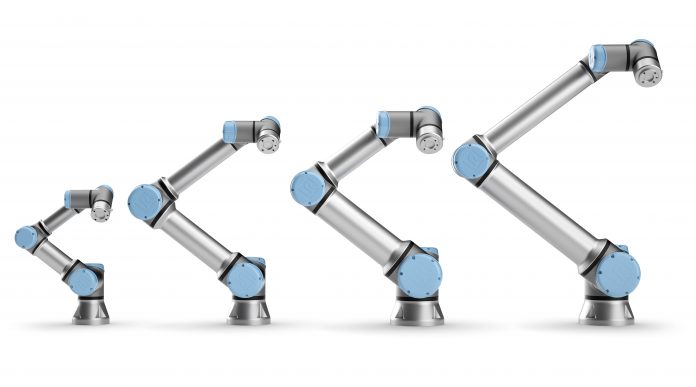

Mr Mase adds that the strength of cobots lies in their size, price tag, and versatility.

“This is important to local manufacturers as other comparable countries such as Japan, South Korea, USA and Germany continue to improve their competitiveness by strategically increasing their robot density (robots per 10,000 employees),” he says.

Mr Choo echoes this sentiment: “Our manufacturing landscape has evolved significantly over the past decade and Covid-19 has reinforced both a need for flexibility and independence in our production.

“There is a growing realisation that manufacturing businesses are reducing their reliance on external suppliers to maintain control over their own production processes.”

Sectors for growth and demand

“Sectors with serious labour shortages are amongst those who will reap the greatest benefits by deploying automation,” says Mr Mase. “Arc welding and plasma cutting are two of the newest and fastest growing sectors for cobots, globally. This presents a great opportunity on our local shores too.”

He adds that start-ups (or Small Medium Enterprises (SME’s), OEMs who are integrating cobots into their systems and offerings, machine tending and low-volume/ high-mix metal fabrication job shop businesses are also key sectors for development.

Mr Choo adds: “I believe there are still a decent number of machine shops that still run mostly with labour-tended CNC or press machines. Similarly, MiG welding consumers are also looking for cobots to automate the welding process.”

Adding value

The biggest driver for any business is that of ‘value’. For Universal Robots, value goes beyond its offering.

“The people within our organisation add value every step of the way,” says Mr McKew. “Adding more like-minded, driven people to our local contingent is of great benefit to our customers. It shows our commitment to the market and looks to bolster the customers’ bottom line and efficiencies.”

Mr Choo adds: “Having confidence in our brand will ensure that more companies feel supported and comfortable enough to take their projects in-house.”

Mr Mase says: “I am on a mission to help as many local businesses as possible to realise just how much they can improve their efficiency, safety, and quality through cobot technologies.”

For more information, visit universal-robots.com.