Collaborative robots, fondly known as cobots, are emerging as a force for good in the ongoing battle against COVID-19.

Whether they are disinfecting and sanitising, conducting COVID-19 tests, helping to manufacture personal protection equipment (PPE) or ramping up respirator production, cobots can work alongside humans safely or on their own.

They are the answer to accelerating repetitive tasks in the manufacturing environment while simultaneously addressing concerns around social distancing and the safety of employees.

Industry pioneers, Universal Robots have noted an uptake in the demand for its cobots in various industries across the globe.

“Locally”, observes Darrell Adams, Head of Southeast Asia Oceania for Universal Robots, “the pandemic has seen many companies shifting towards robotic technology to help ramp up production.”

“As the fastest growing sector in the robotics industry, cobots are easy to program and deploy remotely. Viewed as a ‘niche’ product in the past, cobots are now the fastest growing segment in the industrial robotics sector.”

By 2025, cobots are expected to jump from niche status to thoroughly mainstream, accounting for approximately 34 per cent of global robot spend.

Disinfecting with cobots

The pandemic has seen massive increase in demand for effective deep cleaning and disinfection technologies that do not involve direct human contact with potentially infected areas.

In mid-April, researchers at Nanyang Technological University (NTU) in Singapore unveiled the eXtremeDisinfection roBOT (XDBOT), which comprises a UR5 cobot fitted with an electrostatic spray nozzle all mounted on a mobile platform.

Researchers programmed the cobot to mimic human hand movements so that it can get into hard-to-reach areas such as under beds and tables – a feature that has been missing from traditional disinfection robots that are not as dexterous.

COVID-19 testing with cobots

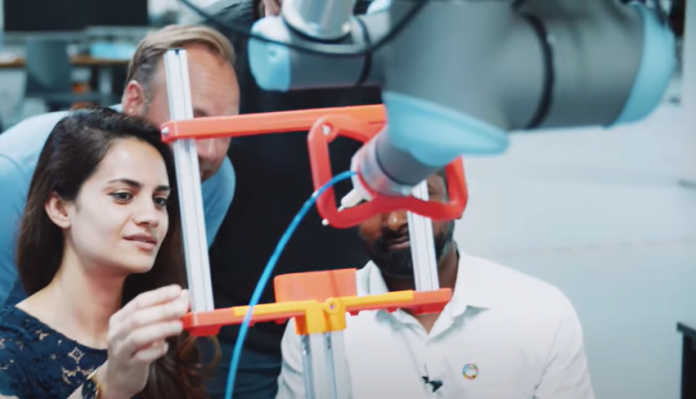

COVID-19 has also resulted in unprecedented demand for medical testing. In response to this extraordinary demand, Universal Robots co-founder, Esben Østergaard turned his creative energies to the design and development of the world’s first autonomous throat swabbing robot launched by Lifeline Robotics, a company he co-founded with the Maersk Mc-Kinney Moller Institute at the University of Southern Denmark (SDU).

This robot uses UR3 cobot arms fitted with a custom 3D-printed end-effector and the process takes around seven minutes.

Local support, service and maintenance as well as training offerings through our online UR Academy, global network of Authorised Training Centres, and UR’s extensive UR+ ecosystem is also locally available.